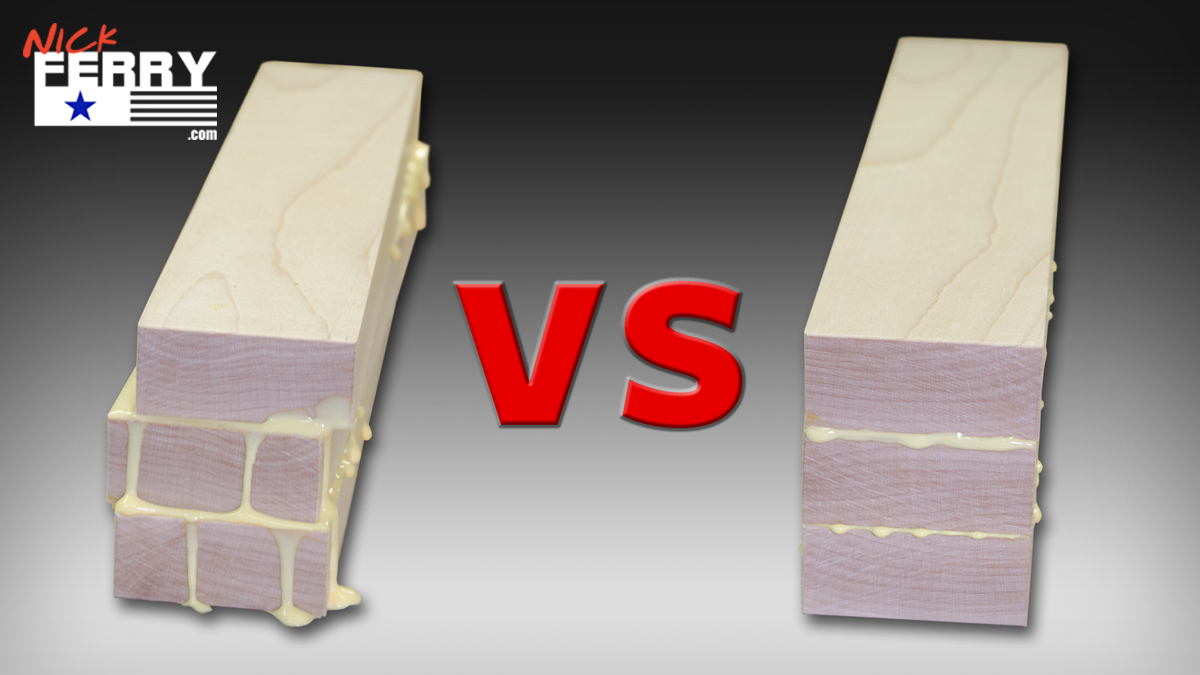

Gluing wood together to make larger and thicker pieces can be a problem. The glue makes everything slide around making it almost impossible to get the boards even and flush. I was recently hanging out with my friend Rich when he noticed my technique to keep the wood from sliding around before I get everything clamped together. I never really gave the technique much thought. After he pointed it out and we talked about it for a bit, I realized maybe not everyone does it this way. So I figured I would share it. It’s probably the easiest way I have ever tried to glue wood laminations together. I feel it can’t get any simpler. You probably have everything needed to do it already. No need for clamping cauls, finish or brad nails, CA glue or salt. Let me know what you think!

TOOLS USED

14 Responses

I like it, Nick. Any tricks for gluing up pieces wider that your parallel clamp? Cutting boards? Workbench tops?

thanks – there are a few – I hope at some point I can make a video on that as well – wood cauls and wedges can help immensely in glue-ups

your clamping video was very helpful. I enjoyed it a lot.

that’s great to hear – glad you enjoyed it and found it useful

WOW. A D’oh moment!!! GREAT tip

How about after the first F clamps, wipe down the sticky on one side, then use opposing Fs one by one, and wipe down the sticky on the other side? Then finish up w/ the smaller Fs. It adds one (short) step but would make final clean up a lot easier, no?

ken

thanks – I have done that as well – I forget which videos I show it in but I do that probably more often – I just like showing various ways to do it

What size brayer do you recommend?

1 1/2″ is what I reach for the most

Hello Nick,

What’s the best way to clean off the glue roller. Do you just let it dry, or rinse under hot water?

I’ve always been a rinse guy (takes all of one minute) but I have been meaning to try and let it dry on these brayers and see if it peels off as well as silicone

LOL… 1 clamp short??? Just goes to show, we never can have too many clamps. 🙂

I agree 100%!

Great video Nick thanks! Looking for some advise….I going to be building up some 3″ thick boards using 1″ boards. The 1″ boards are S4S and are fairly straight but not perfect. Do you think it’s necessary to joint and plane the 1″ boards before gluing up or just do it on the built up boards? Thanks!

many variables on this – if they are narrower for leg stock, you’ll have an easier time than if the are wider for a workbench top – and of course it depends on how bad they are – The boards I did weren’t all that bad – in a perfect world, jointing then planing is ideal but many time not entirely needed – I wish I had a more definitive answer but it really is handled on a case per case basis