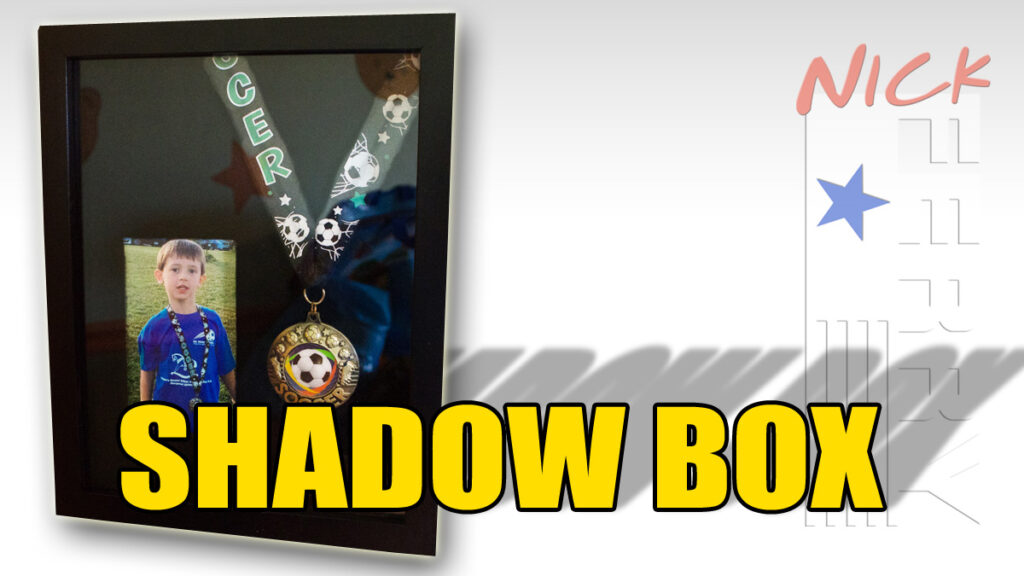

Achievements & milestones can be a funny thing. They can mean different things to different age brackets. My boys tried their hand at organized sports for the first time this year by joining soccer teams. They were each given a medal at the end of their summer season. To an adult, the medal was cheap, not very well made and essentially valueless. To my kids, it was the world! They won a medal & couldn’t wait to tell anyone with ears. To make that moment last as long as possible, I wanted to make a keepsake they could not only cherish now, but could also stir up memories many years into the future. A shadow box was the best thing I could think of to memorialize their achievement. I didn’t want the project to break the bank so I bought some dollar store picture frames for the glass and went with standard pine boards for under a buck as well. Armed with those supplies, some leftover fabric and paint I was ready to build.

If you know ahead of time you are going to paint a project, less expensive lumber can be used. Do a bit of digging & you can find some decent pieces to use.

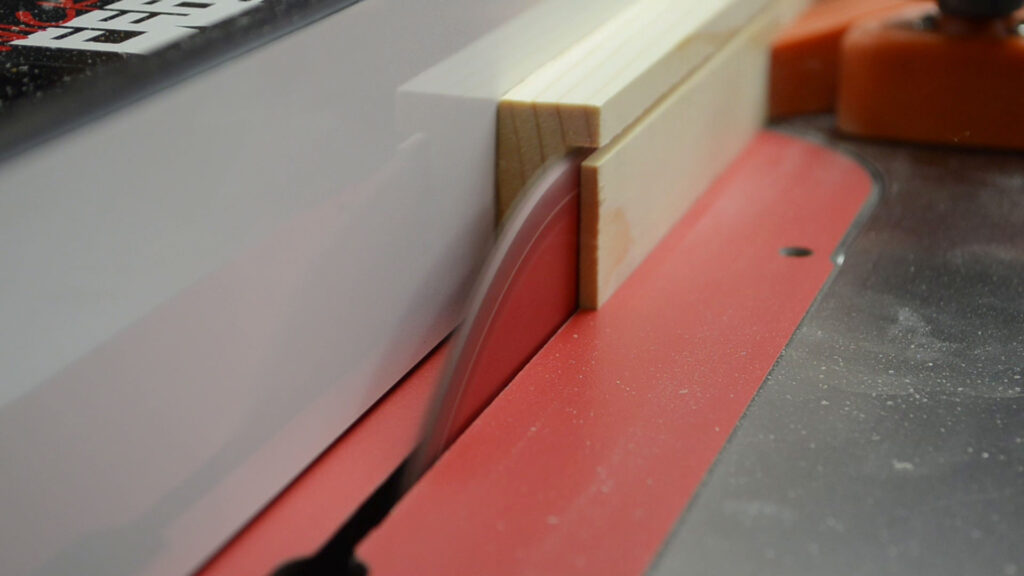

I began by ripping a tiny amount off the factory edge to give it more uniformity.

I flipped the board so the “new” edge was against the rip fence & cut the pieces to a final width of 1 1/2″.

The remaining piece was cut to the same width as well. One 4′ board was enough to make 2 frames.

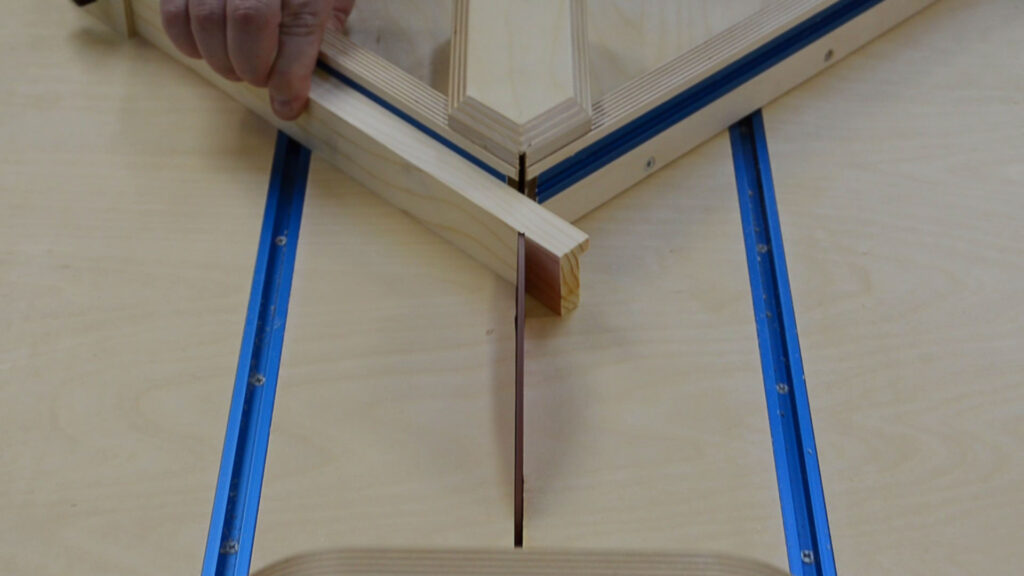

To make the rabbet, I cut a 1/4″ deep groove along the entire length of the wood.

Finishing the rabbet, I made a 1 1/4″ deep cut to meet the first cut.

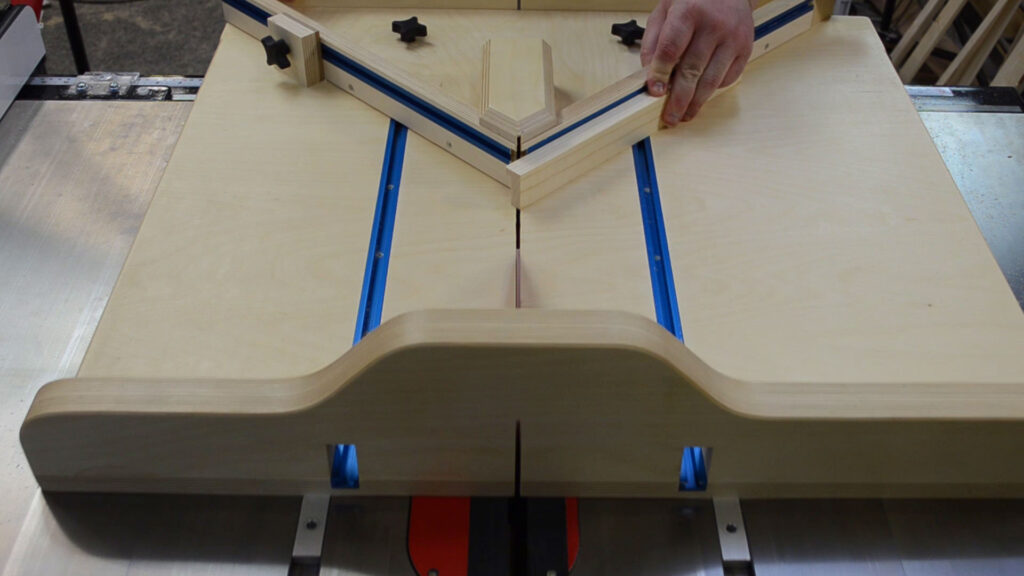

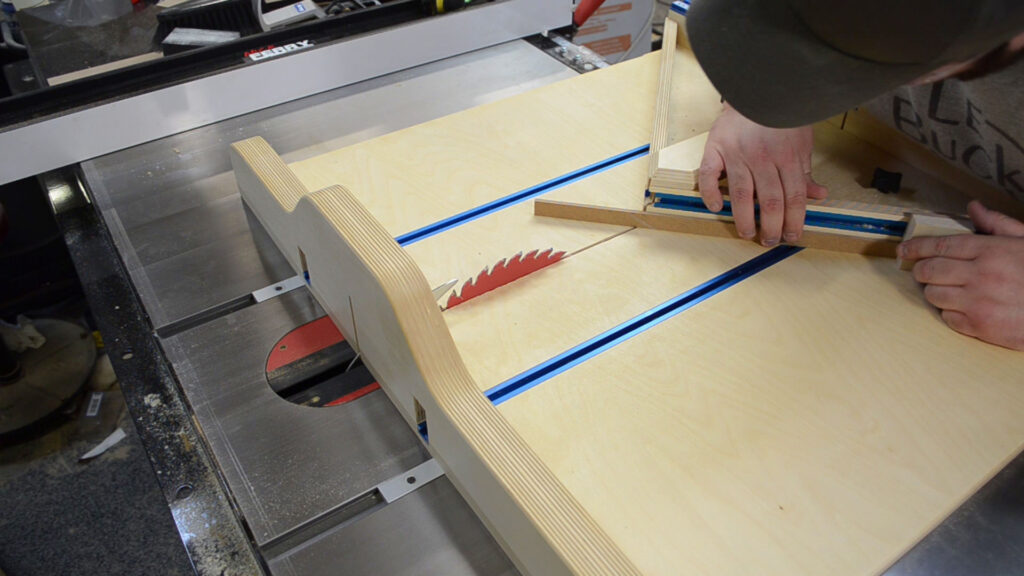

Using a miter sled, I cut 45° angles on all of the pieces.

Make sure the miter cuts are oriented so the rabbet side of the piece ends up being the shorter side.

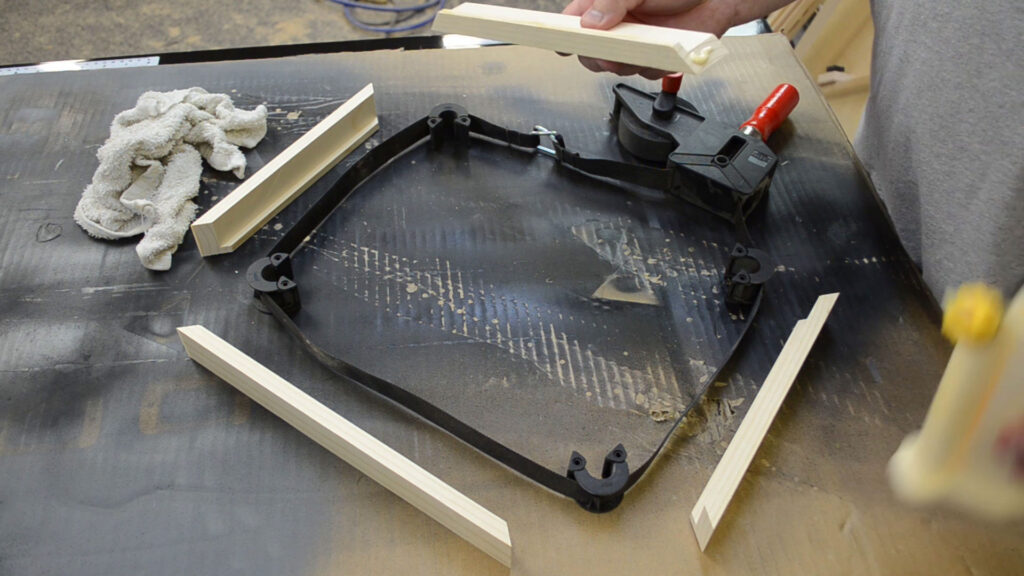

After a test fit, I applied glue to both ends of each piece. Using a strap clamp tighten everything so all the miters line up nicely.

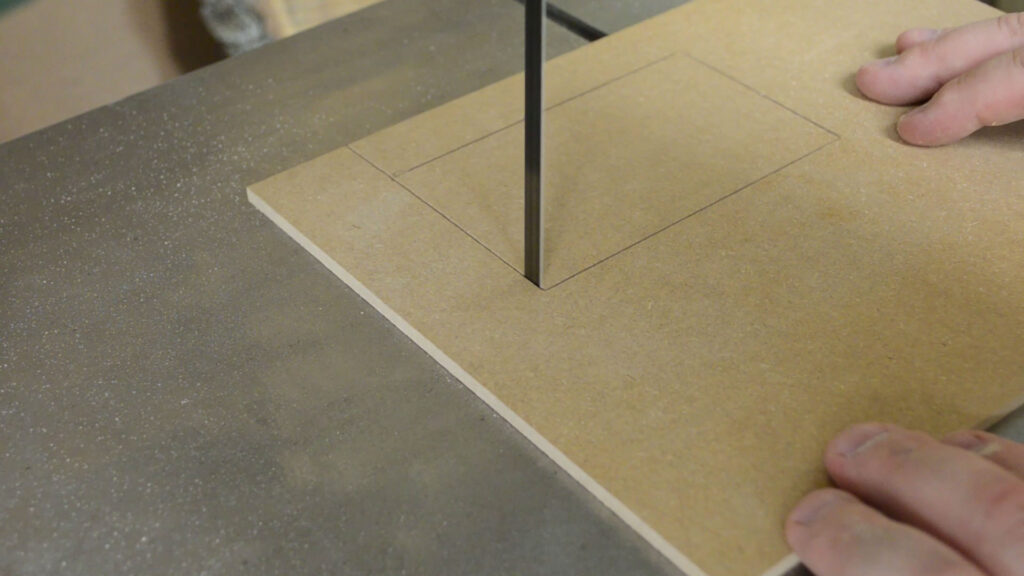

Using 1/4″ MDF I cut the back boards to 8 1/2″ x 11″.

Laying out my sons medal and 3″ x 5″ scrap piece, I traced the scrap to indicate where I was to cut out the photo holder.

My bandsaw made quick work of cutting out where a photo was going to be attached later.

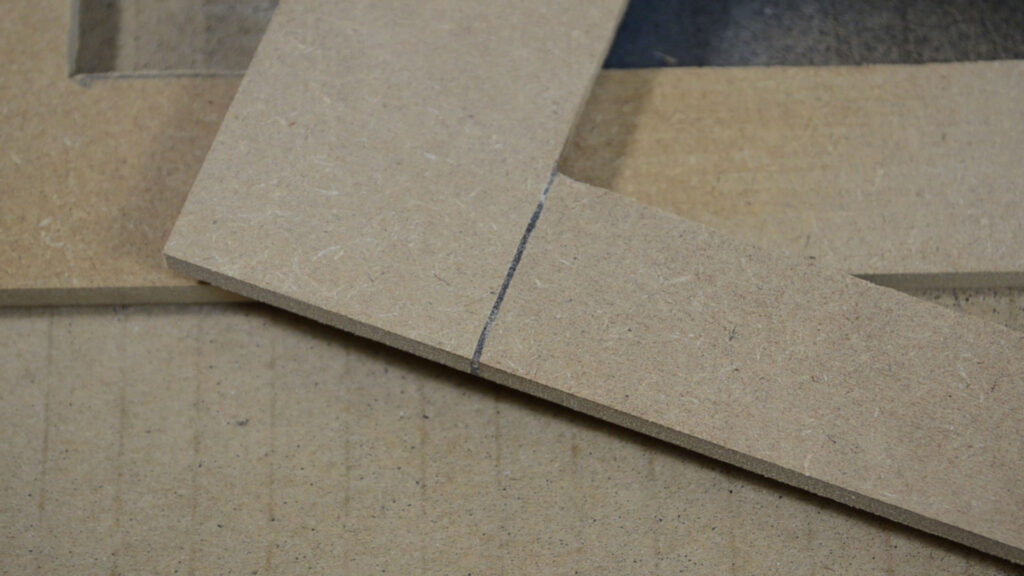

Some 2P-10 CA glue made bridging the gap left behind by the bandsaw super easy.

After some quick sanding you can see the CA glue did a great job.

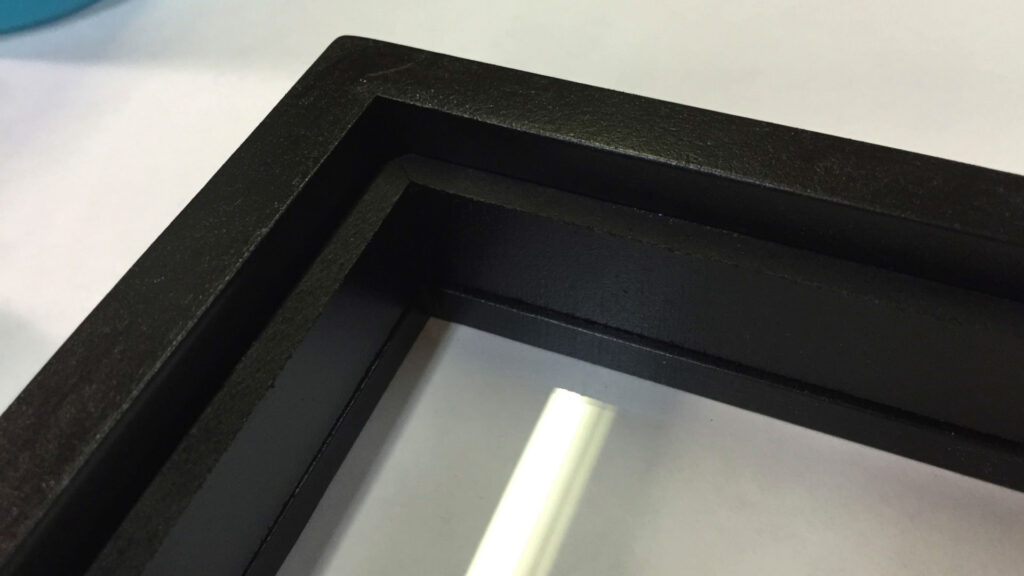

After some finish sanding I noticed one miter had some killer grain continuity. If more corners were like this, I would have reconsidered painting the frame. Unfortunately the grain only matched up like this on one joint.

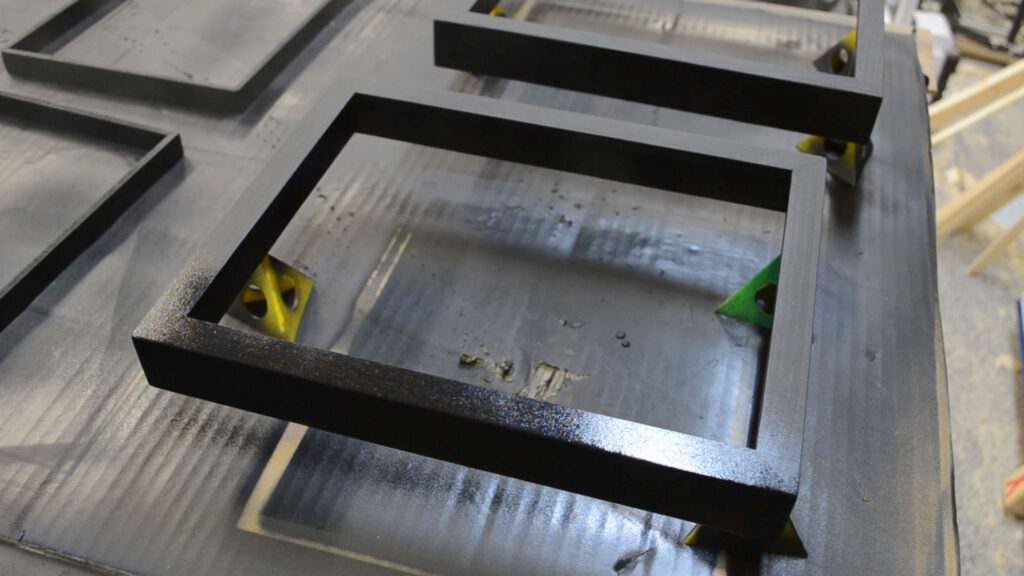

Cut several strips of 1/4″ MDF for the parts to make up the spacer frame.

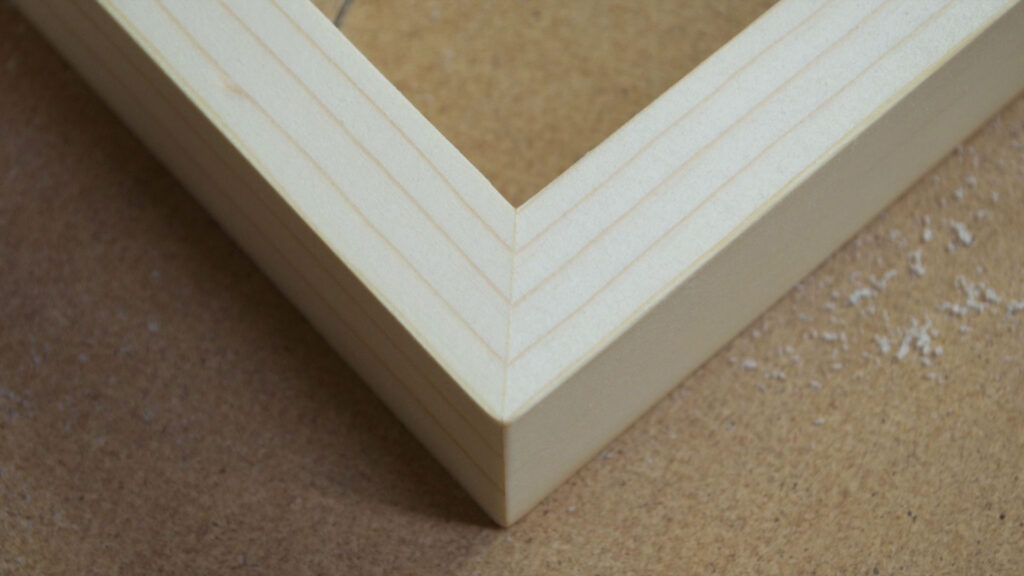

Cut the ends of these to 45° as well. Make the final lengths of these pieces so they fit inside the rabbet in the frame.

To make quick work of the inner frames, I resorted back to some CA glue to hold them together.

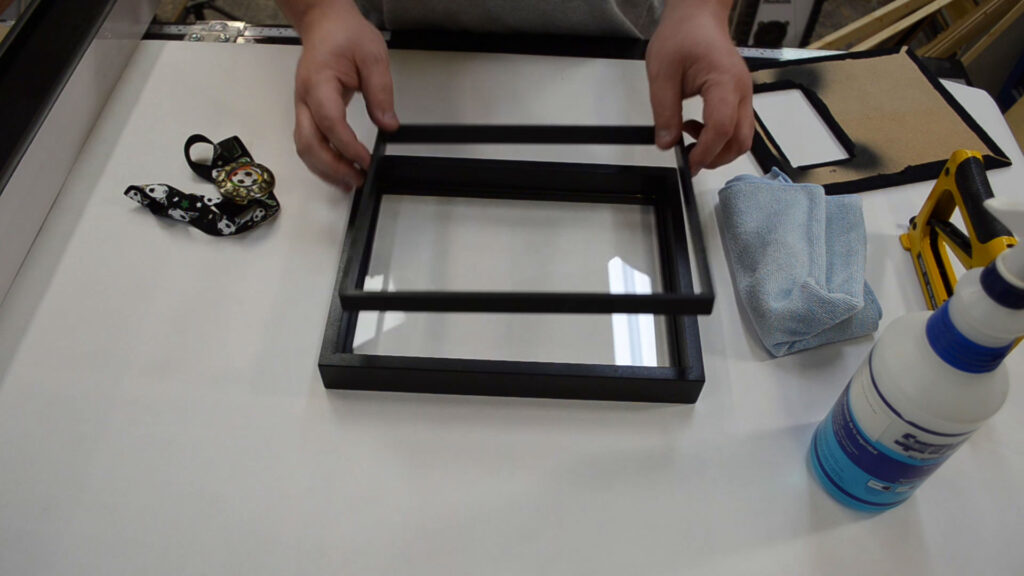

Once completed, the inner frames should fit just inside the rabbets we made earlier in the outer pine frame.

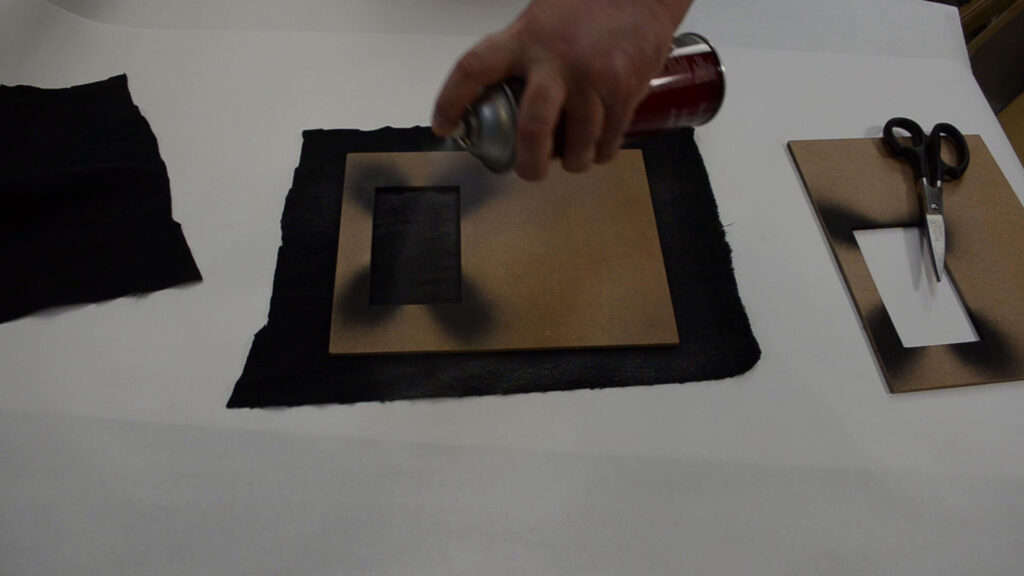

Go ahead and choose you finish of choice. I opted for flat black spray paint as I sometimes feel the muted color of black highlights the contents of the frame more. That and I’m a sucker for black.

To give the frames a bit more protection and a more elegant look, I finished up with 1-2 coats os satin spray lacquer.

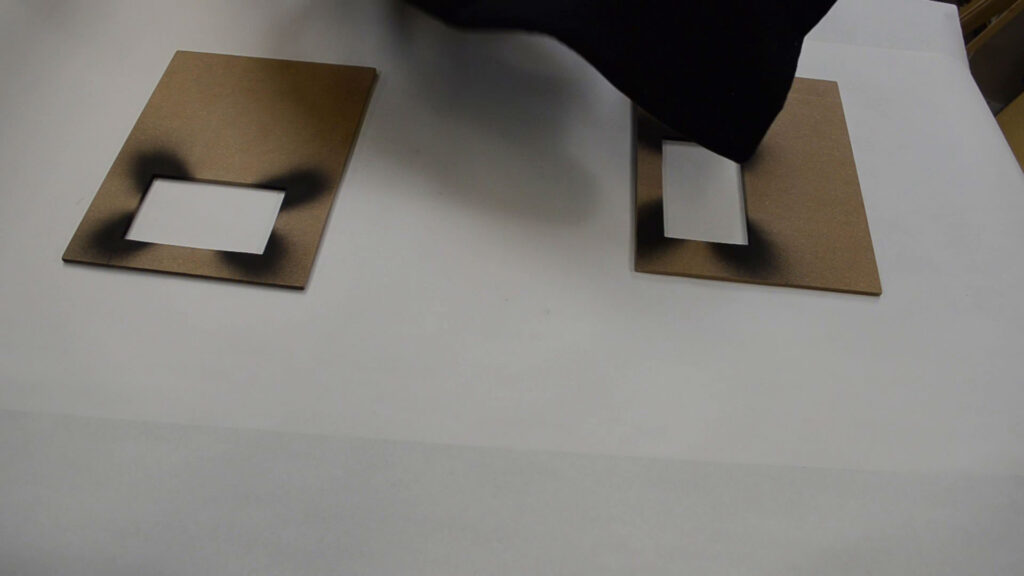

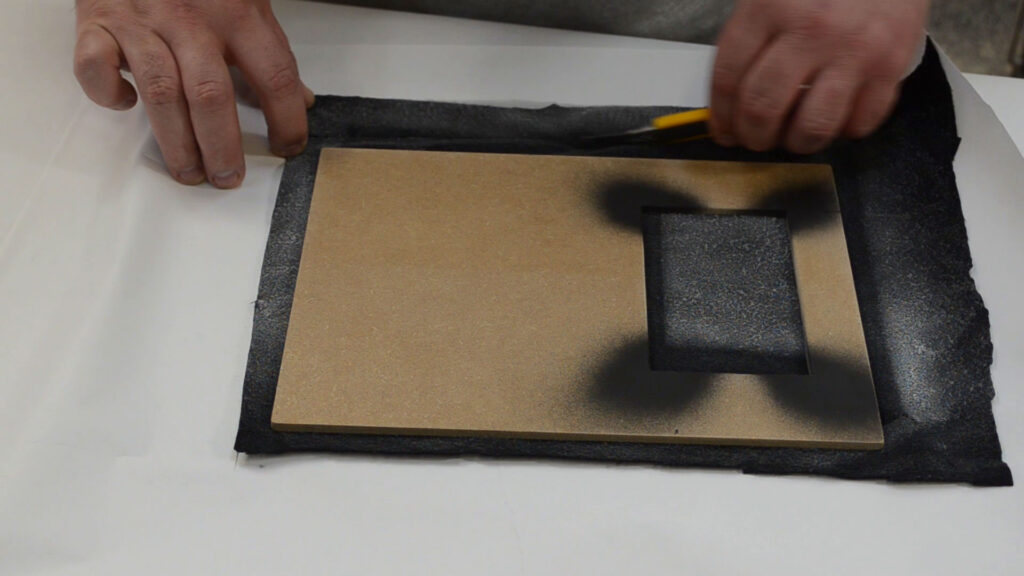

You will notice the corners of the cutouts in the back piece have been painted black as well. This is to eliminate any brown MDF showing through when the fabric cut & applied in the next step.

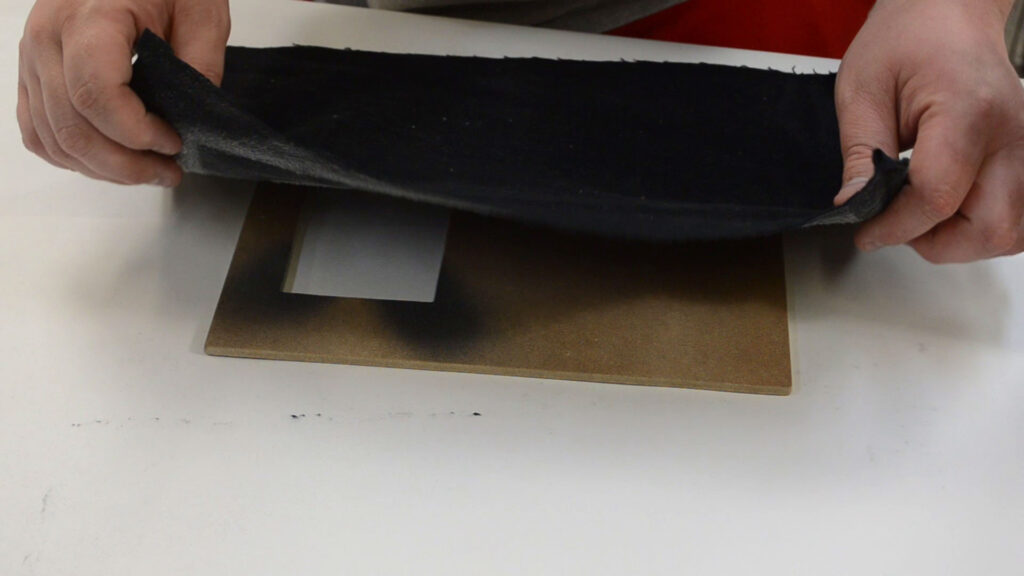

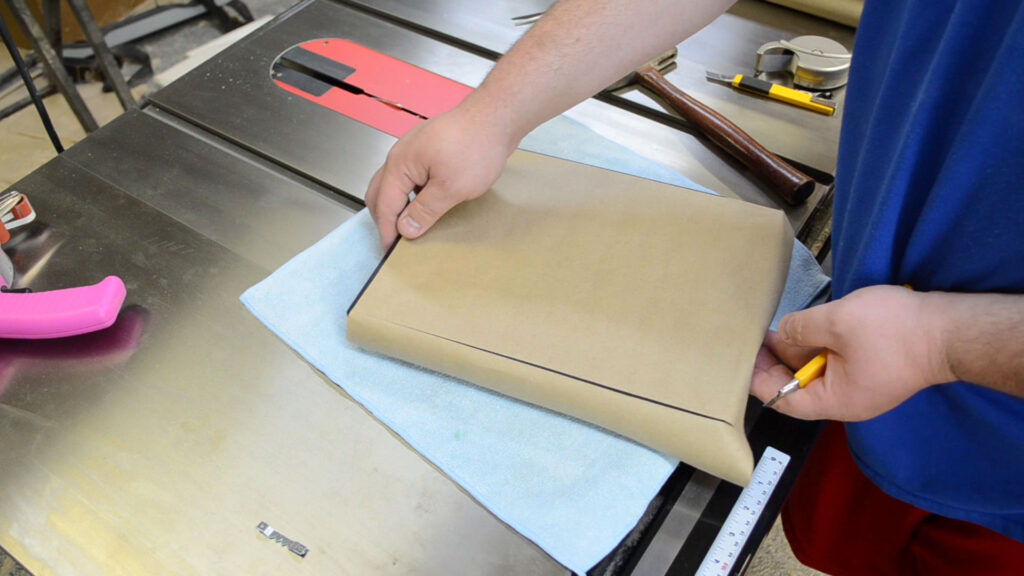

Spray the fabric and/or backer board with some spray adhesive and apply the fabric making sure it is smooth & wrinkle free. You really only have one shot at this as this stuff sticks permanently on contact. So take you time.

Cut away any excess fabric and roll the edges over to the back. Cut an “X” pattern in the windowed cutouts and fold those flaps back as well.

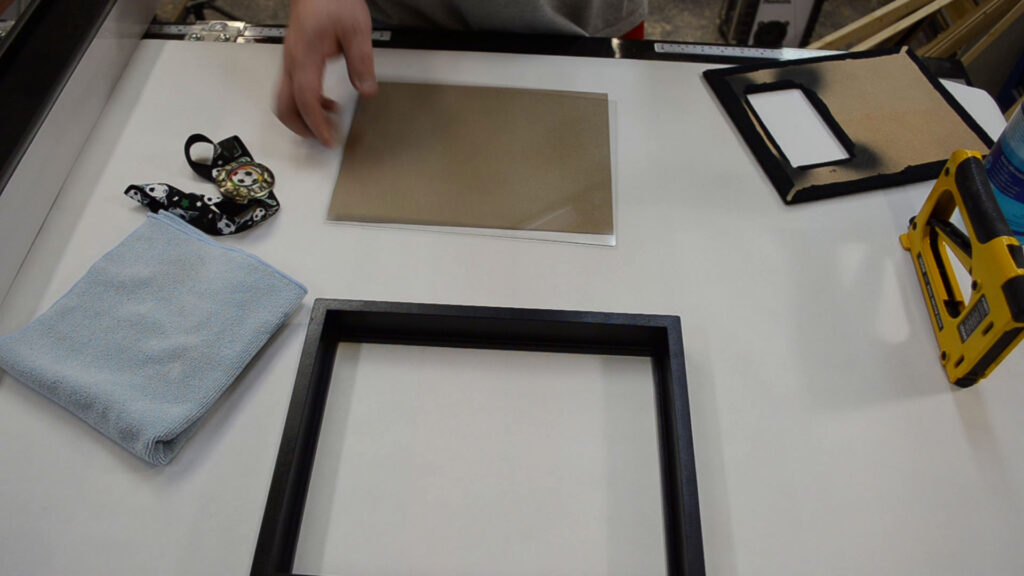

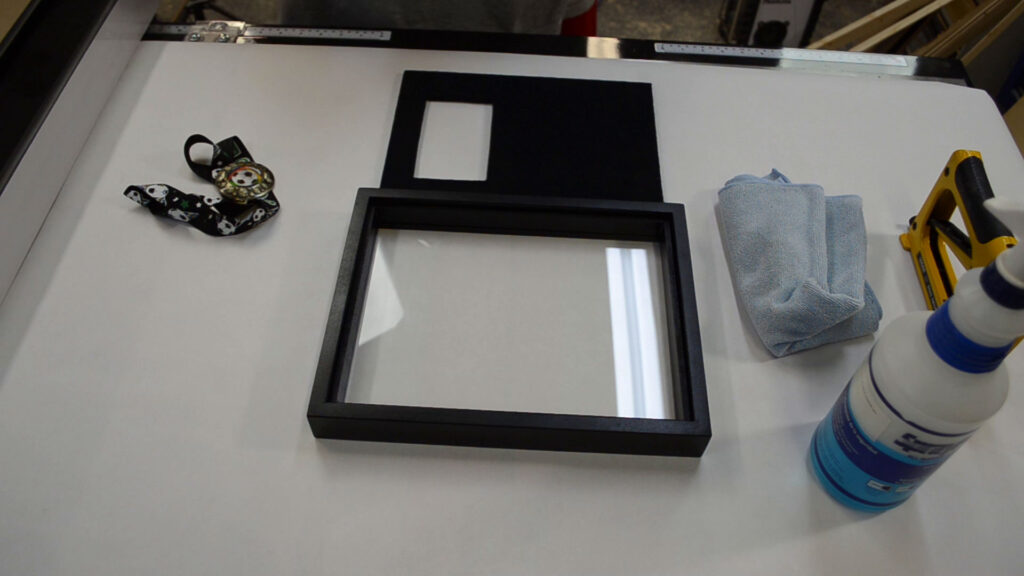

Snag the glass from the $1 picture frame setting it in place. Insert the inner frame, sandwiching the glass in between.

It is a good idea to clean the inside of the glass at this point as it won’t be accessible from here on out.

I placed the medal and the backer board in place and adjusted the medal so it was straight.

Secure the medal in place on the back using a few dabs of glue.

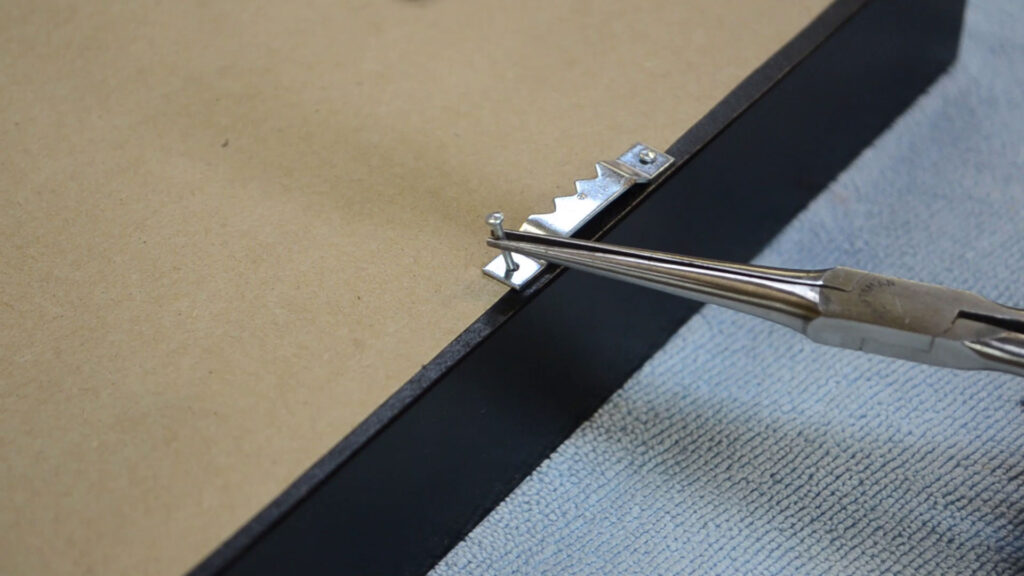

Using a framing point setter, I secured the backer board in place. Framing points come in 2 variations, solid and flexible. The solid ones are used for permanent applications while the flexible ones can be bent out of the way if you want to change the contents of the frame at a later date. I almost always use the solid ones as I rarely change things out on custom frames like these. If it were going to be an annual portrait frame, flexible would be a good choice.

Go ahead at this point and tape your picture into the window.

I like to apply a dust shield to most of what I frame. Use a double-sided tape applicator to apply tape to the entire perimeter.

Some inexpensive kraft paper then gets applied to the double-sided tape.

Crease the paper to indicate the frames edge, and use a sharp knife to cut away excess paper.

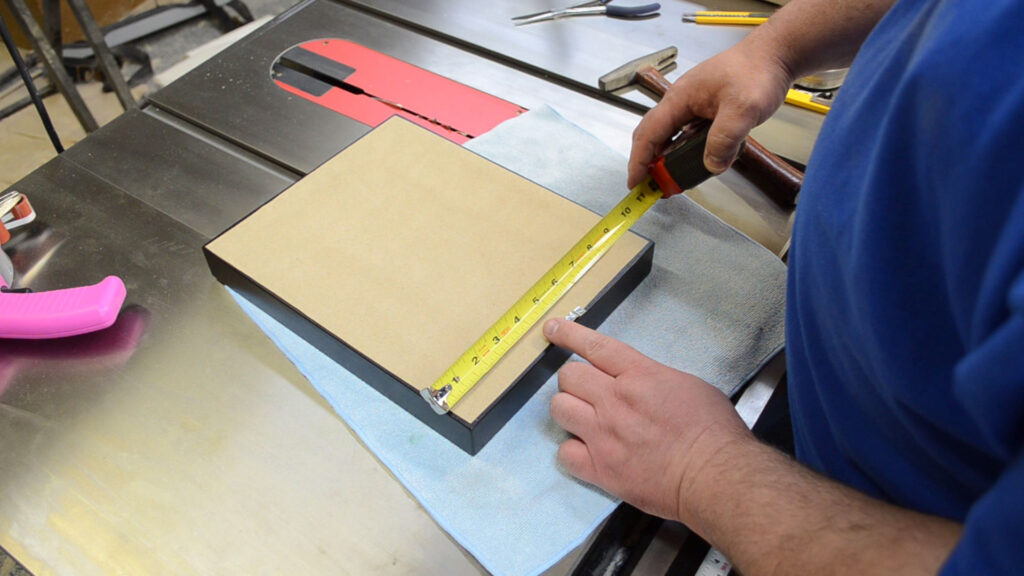

Measure and find center for a sawtooth hanger. Geometric center is good if your frame is symmetrical. If it’s not, you may need to offset the hanger slightly to the heavier side of the frame.

The use of needle nose pliers makes hammering in the small brad nails a lot easier. Even if you don’t have big fat fingers like me, this tip still proves useful.

And done! So for less than $3 a frame I made one for each of my two boys. My wife and I had differing opinions on the final layout so I made one of each. Which one do you prefer? Let me know in the comments your preferred layout!

6 Responses

Excellent project Nick. Thanks for detailed explanation with links to the tools. BTW, I appreciate the quality of your videos, the image quality, sound quality, lighting & framing of the shots are exceptional.

thank you so much Anthony – I put a lot of effort into making my videos & articles the best that I can get them and I’m glad it doesn’t go unnoticed

As a married man you should know the woman is always right. (at least I let them think that)

ha too funny, but also a very good point

Thanks for all the valuable information they really look nice both frames but I think I like the bottom one more. GREAT JOB

no problem Chuck – thank you so much for checking it out – it was a nice fun little project