I have made a lot of spoons over the years and I have never had a good way to dish out the vessel portion of the spoon. I have come up with various ways to this, most of which were rather unsuccessful. Heck, at one point I screwed a hanger bolt into a golf ball with sandpaper glued to it and chucked it into my drill. Not all that effective on hardwoods. A few years back I had imagined a dual axis pendulum setup for my router. Recently a group of online woodworkers had all gotten together to make kitchen utensils and I figured it was finally time to try out my idea. Here is the video documents the jig build as well as a test spoon. Check the video description for a list of all who participated. #utensil2015

Enjoy!

Being it had moving parts I wanted to start with drawing up some sketches to get was in my head on the paper so to speak.

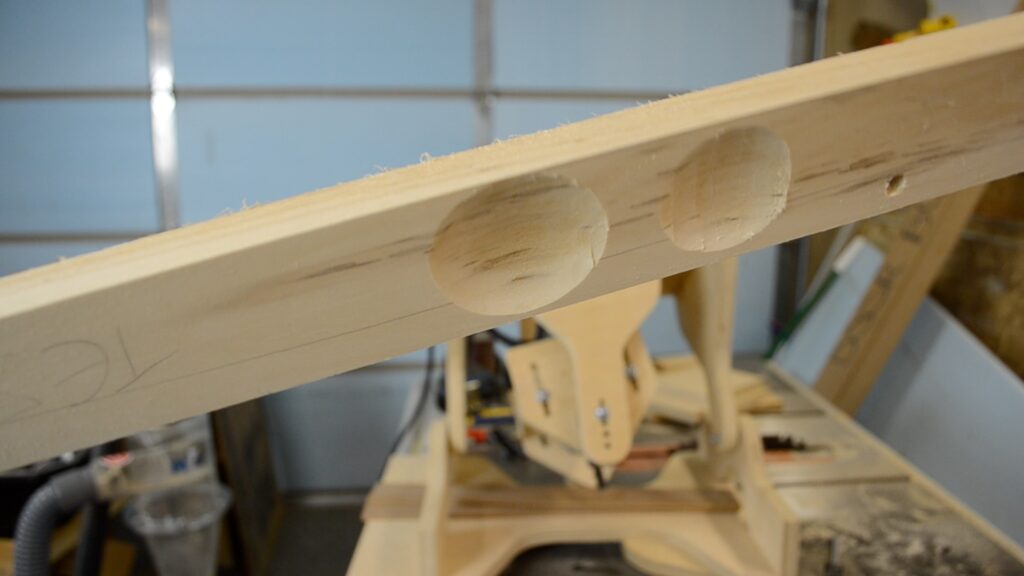

This was the area of the spoon the jig was going to be used for. I guess you could call it the ladle portion.

I got going by cutting pieces to size.

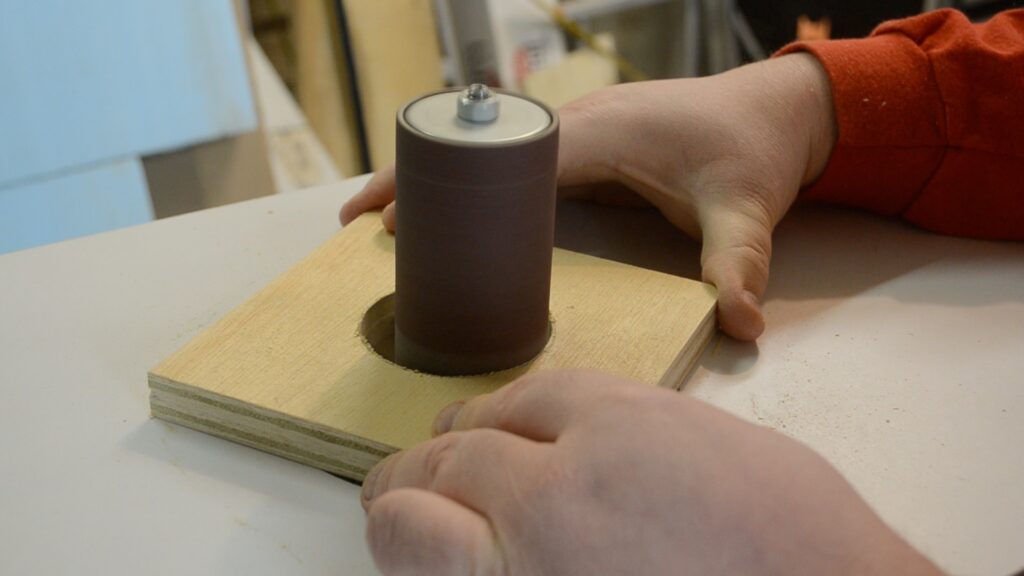

Fitting a jigsawed hole to exact size on the oscillating spindle sander. I went a little bit at a time to ensure a snug fit.

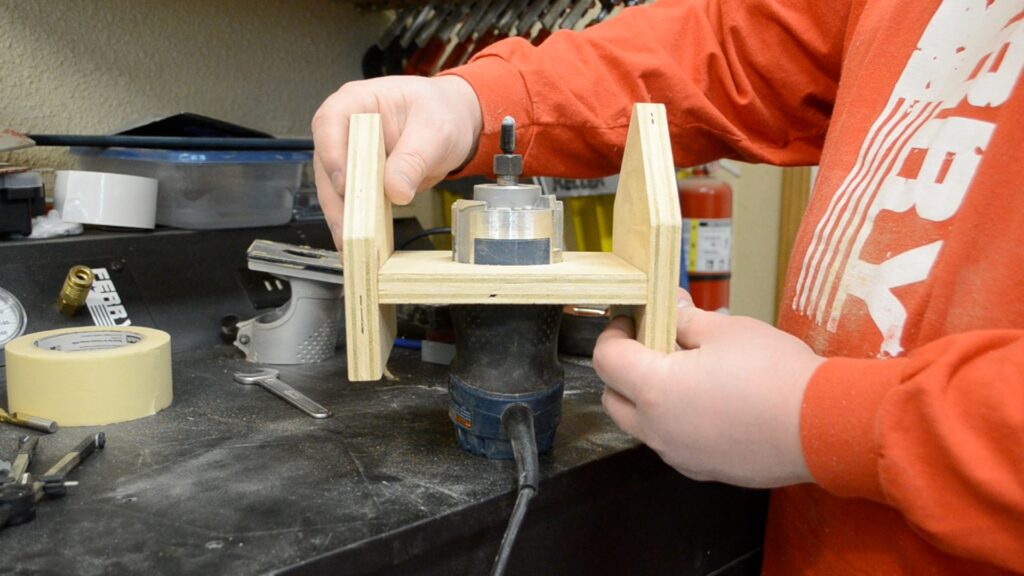

A sort of “carriage” was what I was going for on the router holder.

I could then drill some holes to be connected with a jigsaw to create slots for the adjustable portion.

Threaded inserts of 1/4″-20 would allow for me to readjust the jig as needed.

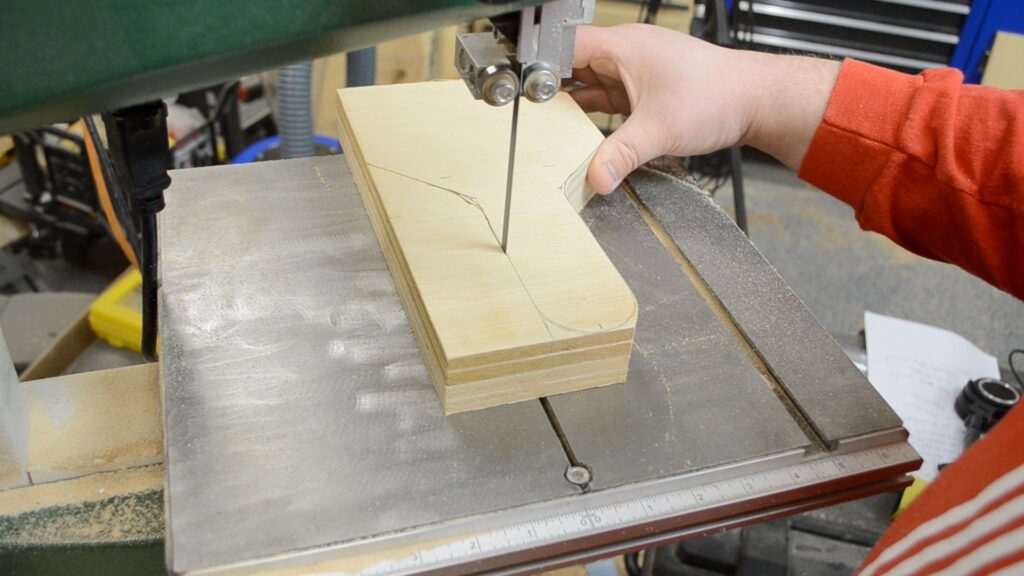

Cutting out parts to act as pivot points

Final shaping can be done one the belt sander

I could then attach a base plate that would allow enough swing travel for the opposing carriage

Mounting the board consisted of an F-style clamp on one end and a screw on the other

I started out with a core box bit but it left the concave portion with bumps and ridges. Switching to a straight bit fully corrected this issue.

The routed portion on the right was done with the core box bit and is slightly bumpy. The one on the left is done with a straight bit and I adjusted it to cut a fair amount deeper and I also elongated the ellipse. The jig a fairly adjustable for both size and shape of the cutout.

After marking out a rough pattern the bandsaw made quick work of removing the bulk of the waste.

Shaping it on the belt sander is my favorite part as it makes me feel like a sculptor, even if it is only for a minute or two. A round-over bit in a router could speed up fabrication time on the handle as another option.

I lieu of a wood burning tool I turned to my butane powered soldering iron to give it a makers mark.

A front and back view of the finished Aspen spoon. I used a light coat of mineral oil and finished it up with some danish oil.

8 Responses

I’m wanting to make some wooden spoons and your jig is impressive is there a chance you would provide the plans so I could build your jig?

sorry I don’t have any plans for it as of right now – If I ever modify it to more than just spoons I may make plans but not sure when the will ever be

Thanks for your help I’ll try to figure out your measurements from your pictures.

not a problem

Thanks for all the thought that went in to this jig. I also appreciate the pictures. I’m about halfway into re-creating your jig. I can’t wait to try it out.

no problem – let me know how it goes!

Finished the jig yesterday. After some tweaking, it works great. I added a couple t-track and hold down clamps, and used a wood burning tool to add some graduations along the slots. Thanks again for sharing ideas and photos. I’d send some pix, but don’t think I can attach files in this forum.

awesome – email me through the contact page – i’d love to see some pictures!