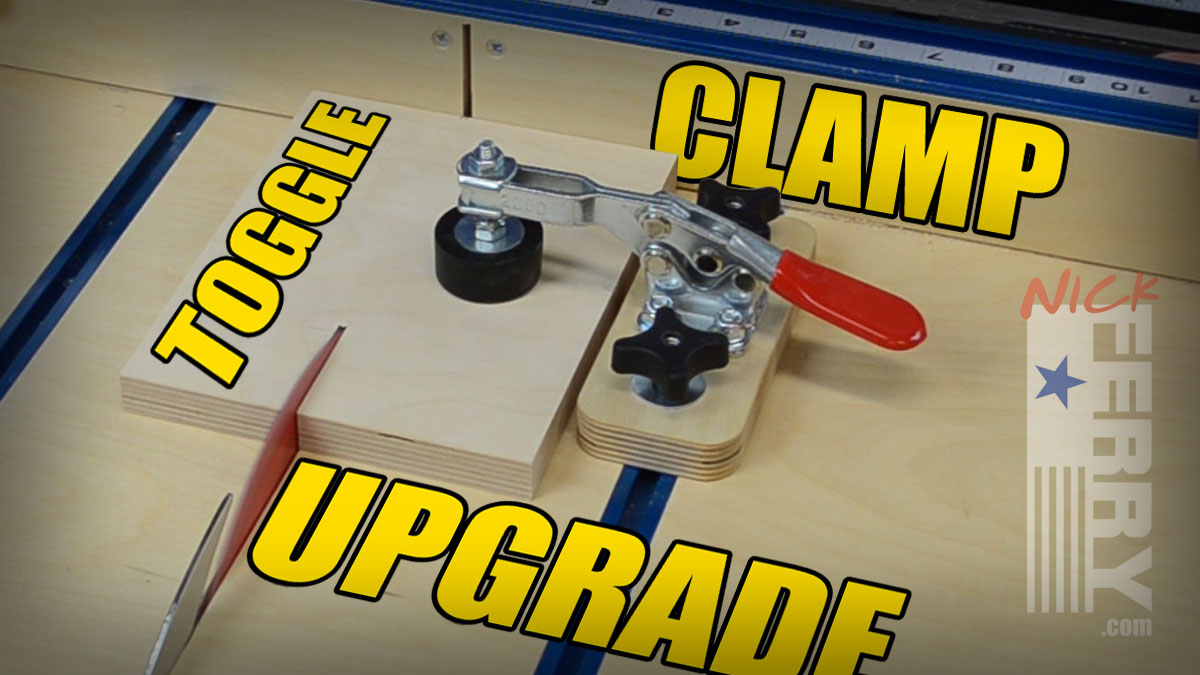

Toggle clamps are essential for woodworking jigs and fixtures. A lot of times they come with a rather small clamping foot. If you are using multiple clamps and/or securing the workpiece against a fixed fence, you may have no problem. It still bugged me that they seemed to let the wood move unless you had them set to an extremely high clamping pressure. Not to mention with a smaller surface area you are prone to denting your workpiece. I can dent projects on my own and don’t need toggle clamps to help me do that. If you want to know how to remove dings and dents, I have a solution for that as well. It was mainly the narrow rubber foot on the clamp that flexed too much and acted as a pivot point that really got me thinking. I have used elevator bolts in the past to remedy similar problems, but wanted the slight cushion rubber would give me. That is when I looked at rubber feet for amplifiers and road cases. Many of them have an integrated metal washer in which the rubber is moulded around. They worked perfectly especially for my spline and tenon jig! If you want to buy these rubber feet, you can click here. Likewise, if you are in need of any toggle clamps, these are the ones I used for this project.

The small, flexible rubber tip, that let wood sometimes move had to go.

These are the feet I was going to use for the new clamp pad. They have a built in metal washer which is perfect to ensure I’ll have a good connection with the hardware. You can purchase the feet here. At the time I got them, they were $4 for a pack of 8. They measure roughly 1.5″ in diameter and 3/4″ tall.

Insert a 2″ x 1/4-20 machine screw into the rubber foot and add a fender washer.

Thread on and tighten down a 1/4-20 nylon lock nut.

This is what the clamp foot should look like at this point.

After removing the old clamp pad (foot), I add a regular 1/4-20 nut for adjustment of different wood thicknesses.

With the adjustment nut in place.

Using the factory alignment washers, install and secure the new foot in place.

The toggle clamp before and after.

The newly modified toggle clamp can be mounted to a piece of plywood to cut smaller pieces on the table saw sled. If you are interested in my table saw sled with built in aluminum miter tracks, click here.

The main reason I wanted to modify the toggle clamp, is to use it in a mitered spline/tenon jig I am making. It works like a charm!

Much more clamping surface area and a much better hold on the workpiece. Can’t ask for more than that!

Well now I just need to modify a couple more clamps. Let me know in the comments below what you think and if this is something you are going to try. If you do, I’d love to hear what you think. Thanks for checking it out!

Well now I just need to modify a couple more clamps. Let me know in the comments below what you think and if this is something you are going to try. If you do, I’d love to hear what you think. Thanks for checking it out!

16 Responses

I like the idea. Rockler and Peachtree both sell larger pads that swivel.

https://www.amazon.com/Large-Toggle-Clamp-Foot-Long/dp/B001ENSLW6/ref=sr_1_2?ie=UTF8&qid=1463158797&sr=8-2&keywords=toggle+clamp+foot

yup – seen those before – haven’t tried them yet, but I’m sure they do the trick

Thanks Nick!

I will definitely be putting a few of these together.

awesome – let me know how you like them!

Simple, yet handy! Thanks so much for posting!

not a problem – work amazingly well for a quick cheap upgrade

What size are your toggle clamps,i have bought a few online and they are really small,I know they make larger ones but can’t tell the size.

did you check the link in the article? those are the ones I used – http://amzn.to/1sjvPXn – they are the regular size

This is an awesome idea. Thanks for posting.

no problem – thanks for checking it out Steve!

Thank you for the great info! I’ve ordered 4 of these clamps, and the replacement feet based off of your recommendation.

nice – how are they working out for you so far?

Hey Nick,

Great stuff

I tried 3 times to join your newsletter and never got anything, and yes, I checked the spam box. Here’s my email ***********.net. TIA Mike

I just confirmed you manually – you should get the next one which will probably be within a week – if you don’t, let me know – thanks!

This is great! I have been looking for longer bolts for my Toggle clamps for certain jigs, and this solves it! I did also find some already made on Rockler that I ordered, but in the future I will be using your idea. Great site and great videos Nick! Thanks

thank you – glad you could get some ideas!