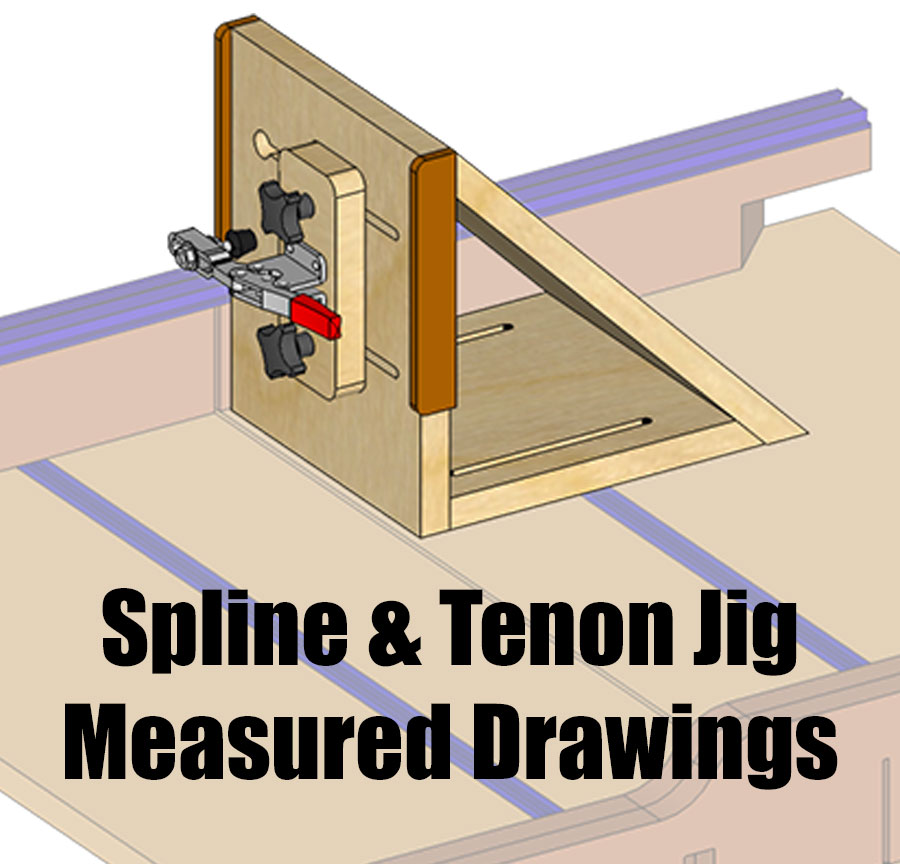

I have gone without a table saw sled for a few years now. It seems as though I was between table saws for just as long. I suppose that would be the major reason I haven’t had one in so long. I needed to change that. I guess going without one for so long had its benefits. That meant I could imagine in my head and plan out as best as possible the best table saw sled I could think of. One major thing I wanted it to do is cross cuts as well as miter cuts. So this is what I came up with. A robust sled that could do 24″ cross cuts for cabinet sides yet jam packed with features that could handle small picture frames as well. Links to all the components used will be at the end of this article. If you want a full set of plans & measurements click here.

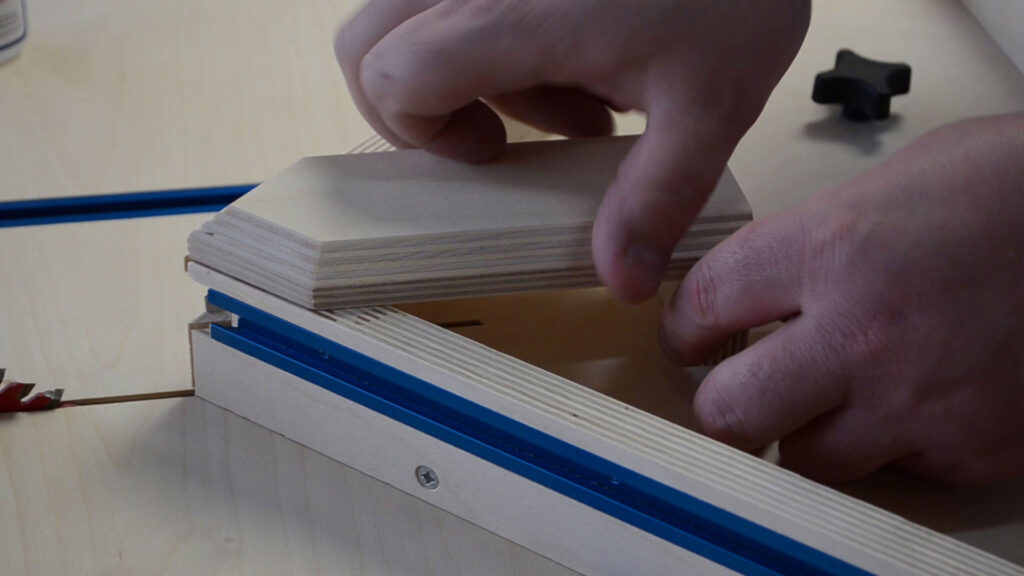

I opted to use 3/4 inch baltic birch plywood for my building material. Stability and ease of use are nice and all, but I love how it looks. I cut most of pieces to size on the table saw.

With my fence pieces to rough size I applied a liberal amount of glue to the surface.

I deployed just about every clamp I own for this step. I guess that is why they say you can never have too many clamps.

With so many clamps in place, it was hard to wipe up any glue squeeze out. I cleaned the majority of this up using a chisel.

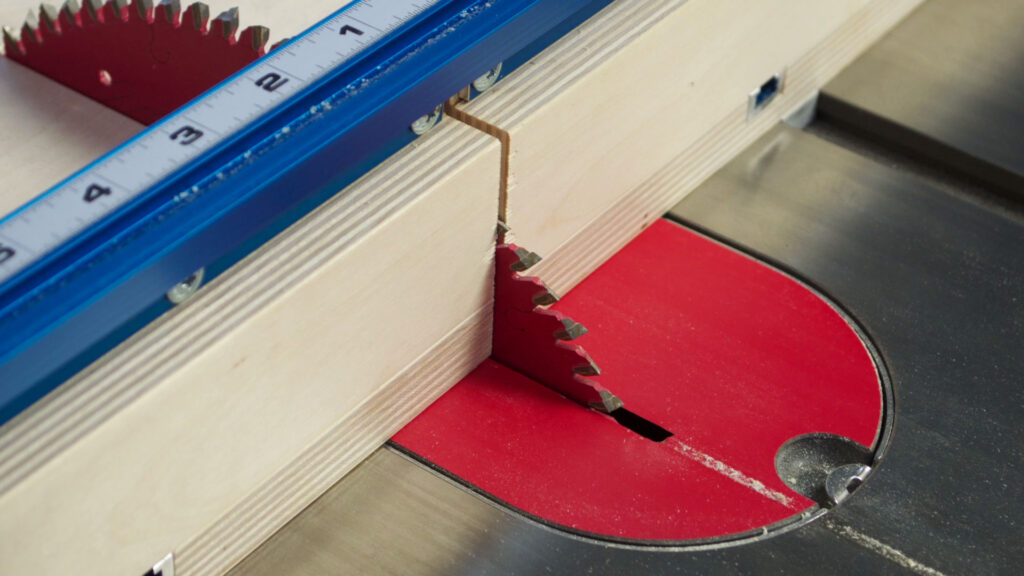

Once most of the glue was cleaned up, I cut the fence pieces down to their final sizes.

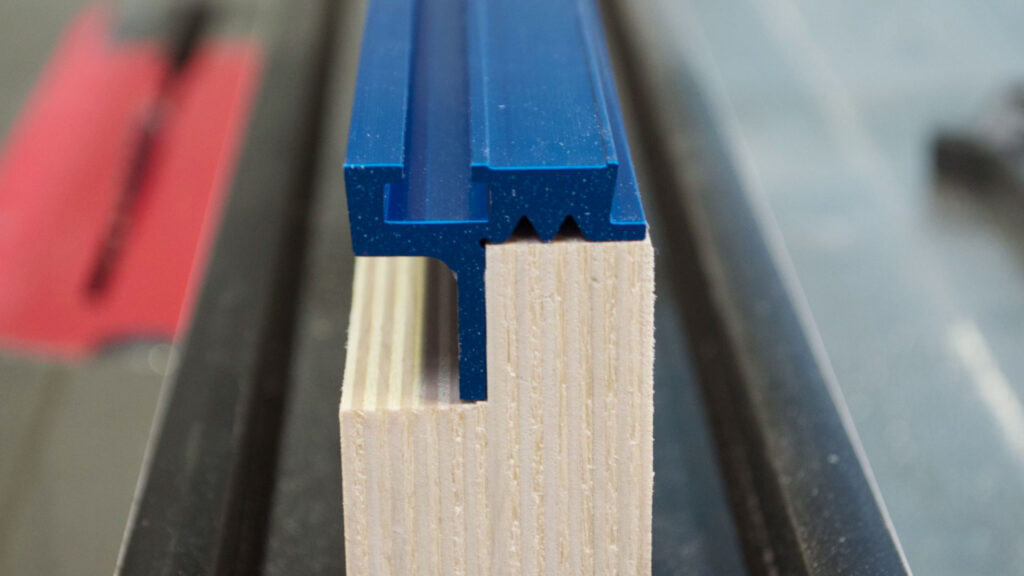

A 3/4″ by 3/4″ rabbet was cut on the front fence to accept a piece of Kreg® Top Trak.

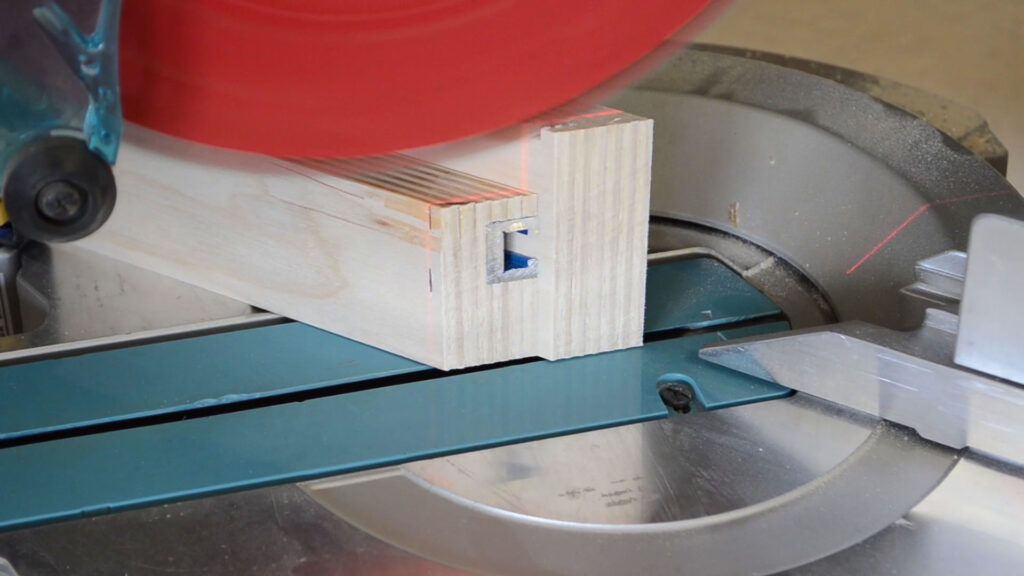

The Top Trak can be cut using the miter saw.

I played around with different fasteners to secure the aluminum. Just about anything will work but I can be picky on how the final product looks. I settled on these screws.

Pre-drilling the aluminum is super easy being it is so soft. Then it’s just a matter of installing the screws to secure it in place.

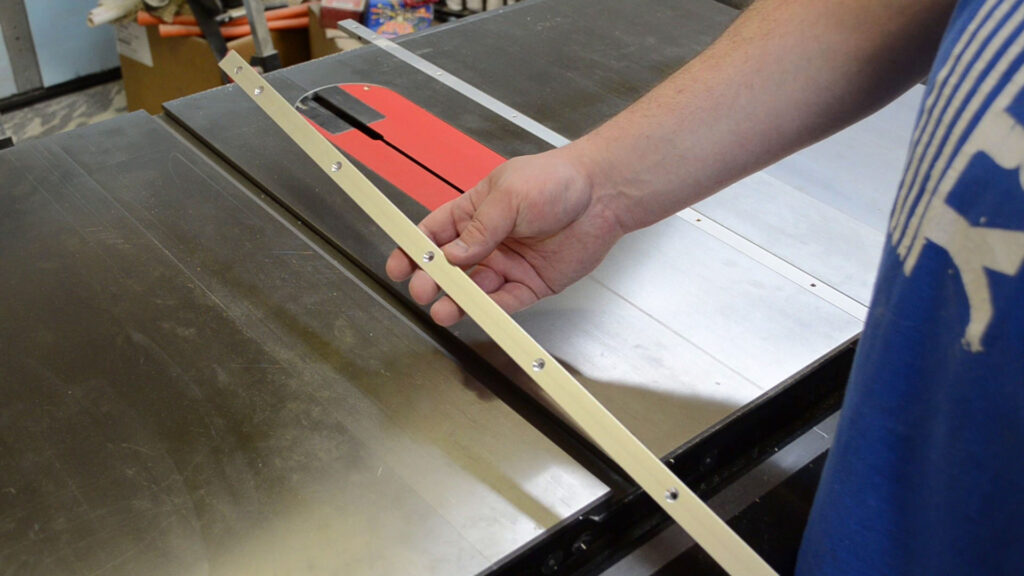

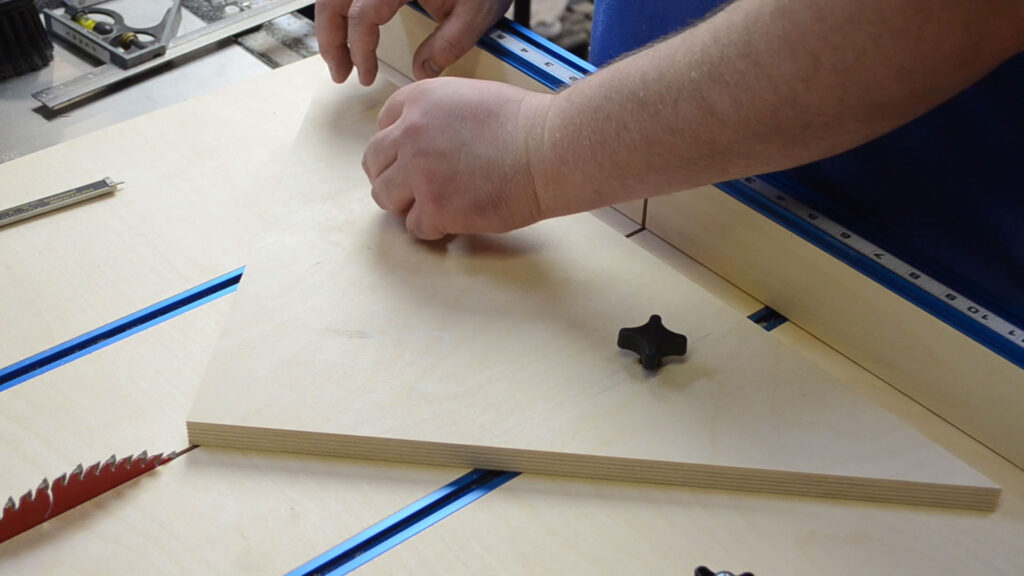

The adjustable aluminum miter slot runners made the whole process go a lot easier but you could substitute for hardwood. I like these jig & fixture bars from Kreg® because of their stability and adjustability.

Using a few dimes I raised the miter slot runner up slightly so I could glue them temporarily to the sled base.

If using the aluminum runners, use CA glue to attach them before using screws. If you opt for hardwood you can use standard wood glue.

Once the glue is dry, finish securing the runners with some screws. I like to hand tighten them to avoid stripping them out.

Layout the cut lines on the back fence, cut it out on a bandsaw and sand to the cut line.

Using a 3/4″ dado stack set to 3/8″ deep, I cut 2 dados to accept the Mini Trak miter track.

Using 1/2″ long #6 screws, I clipped a bit over 1/8″ of the length to make certain the screws were not going to poke through the bottom of the sled base.

The Mini Trak works great with 1/4″-20 hexagonal bolts. Needing a way to insert the bolts and remove them, I made a 3/4″ wide by approximately 1 1/2″ long cut. In hindsight I would have used a bandsaw and made the slots 1/4-1/2″ long to accommodate longer fasteners for future use. I may change this at a later date.

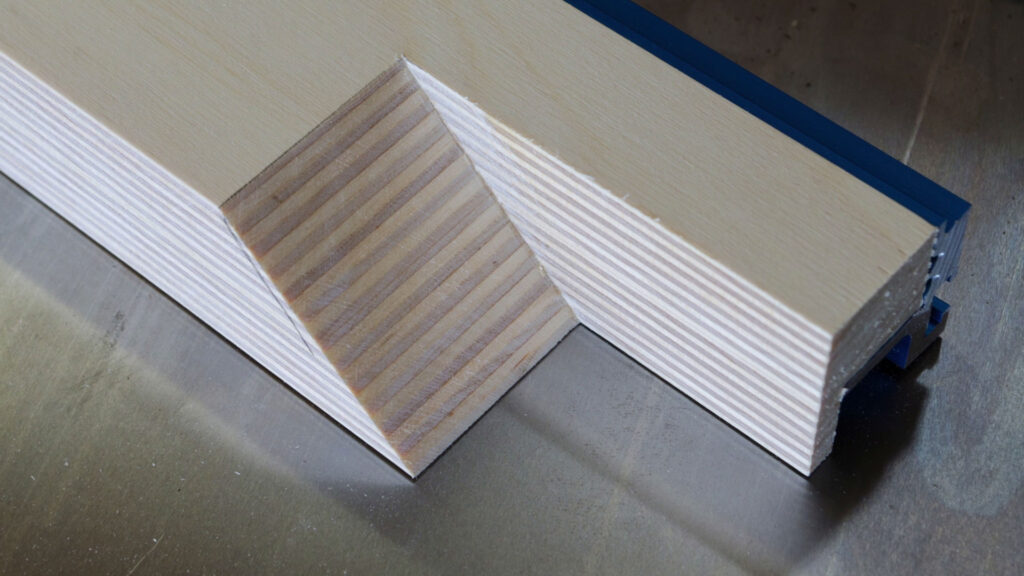

A couple of cuts on the table saw, and a notch is made in one of the fences to allow for most stock to be used in the miter sled portion.

To that same fence I added a 1/8″ chamfer to the bottom to allow for saw dust accumulation.

I have a SawStop table saw that senses conductive material touching the blade (such as skin). If you have a SawStop or similar technology saw, make sure the safety feature is turned off and in bypass mode before cutting any conductive materials such as aluminum. I also made the aluminum kerf quite a bit bigger to make sure the blade is no where near the metal during normal operation.

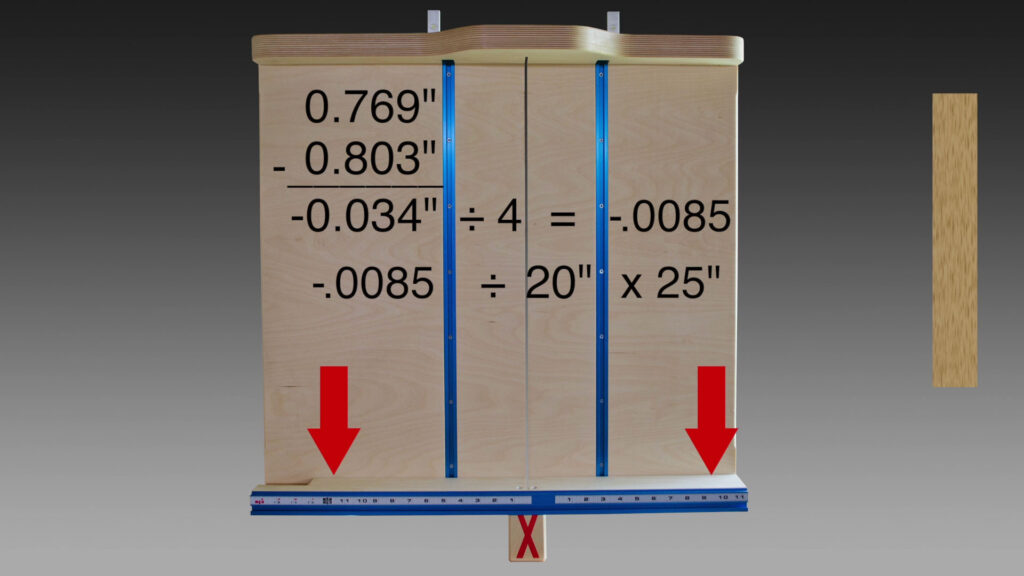

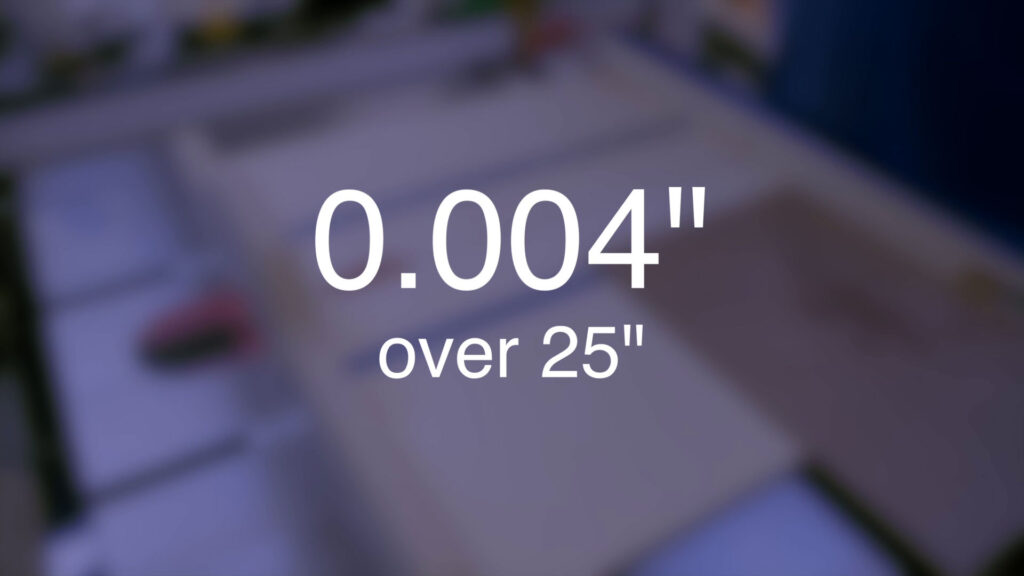

I employed the five cut method to calibrate and adjust the sled. I explain this quite simply in the video. It may sound or look complex but it really isn’t. It essentially is just a matter of making five cuts and measuring your results. You can see here from this machinist’s square and my test piece that this sled is very accurate.

If you are using a sharp blade in combination with the zero clearance aspect of the table saw sled, chip out or tear out is almost non-existent.

Applying the self adhesive tape measures and installing the SwingStop. I am very pleased with the results.

I began making my miter sled insert by cutting a large triangle, drilling a few holes for some hold down bolts, and installing a couple star knobs.

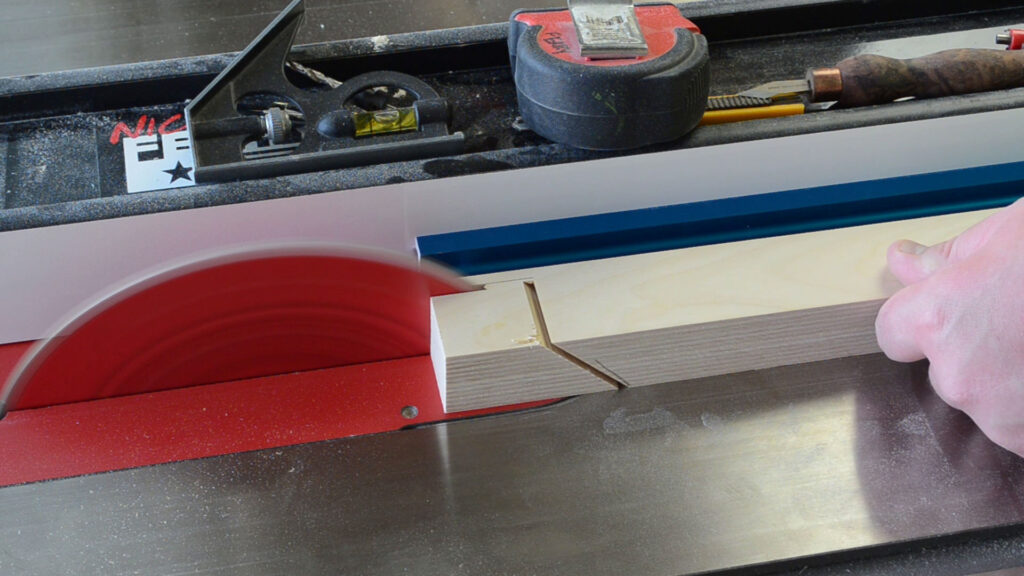

After ripping some pieces to width to act as my miter sled fence, I put a 3/4″ groove in them to allow for some more aluminum miter track.

I cut these pieces of aluminum at a 45 degree miter, and I like to use a wood backer to make it easier and have less burrs.

Again, being I’m on a SawStop, I held my aluminum back at least 1/8″ back from the blade to avoid the blade ever coming into contact with the extrusion.

I also added a blade guard to the miter sled insert for added safety.

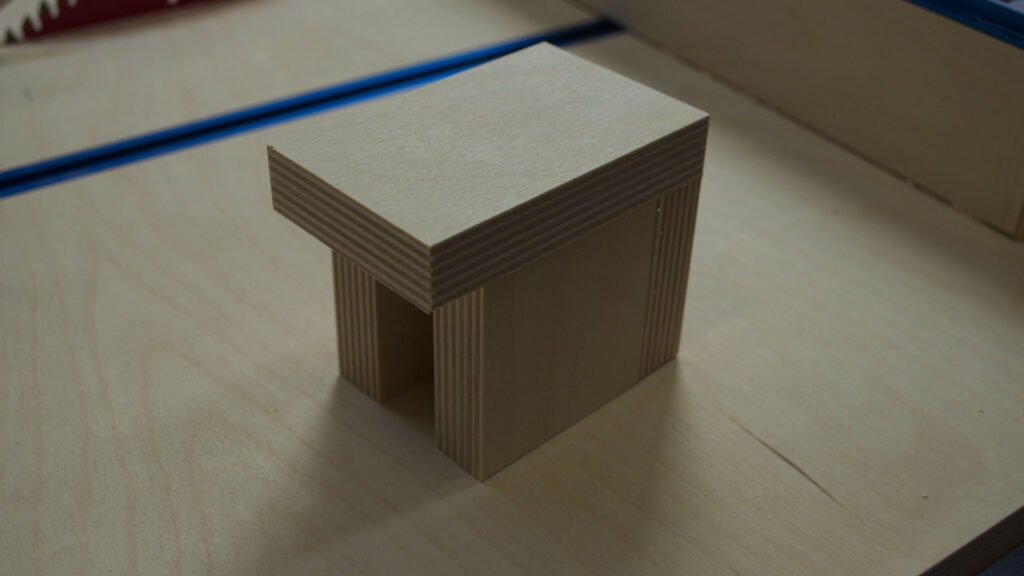

For the cross cut sled portion, I made a small box where the blade protrudes out the back of the saw. Again this is for safety and a visual reference of where the blade exits the sled.

Also for a visual indicator, I used some masking tape to make a stencil so I could paint a red “X” on the blade guard. This may be overkill, but I like the fact that there is a visual to say “don’t put your fingers here”.

Some wipe on polyurethane to all the bare wood, and this sled is done!

LIST OF COMPONENTS USED:

Please note – most of the item links are my Amazon affiliate links and purchases through there help support the show.

1@ 48″ Kreg® Top Trak – ITEM#: KMS7714 – Purchase

2@ 30″ Kreg® Jig & Fixture Bar – ITEM#: KMS7303 – Purchase

2@ 48″ Kreg® Mini Trak – ITEM#: KMS7509 – Purchase

1@ Kreg® Swing Stop – ITEM#: KMS7801 – Purchase

3@ 1/4″ – 20 star knobs for jigs – PART# S7-N12BK – Purchase

1 of each Self Adhesive Tape Measure – ITEM#: KMS7724 & KMS7723 – Left to Right and Right to Left Reading

Table Saw Crosscut & Miter Sled Plans

$15.99

23 pages of high quality, full color step by step PDF plans for the cross cut / miter sled combo I made in episode 58. All downloadable products are non-refundable. On checkout receipt you will be given a link to download the file.

Description

A table saw sled is a jig that is essential in any wood shop. When built correctly it offers improved safety, repeatability and extreme accuracy. This has been years in the making for me and I have put many hours of thought, trial and error into this design. This sled combines both a cross cut sled and a miter sled all in one. These are my most comprehensive & detailed plans I have made to date. I am sure you will love building this awesome table saw sled!

What you get:

- 23 pages of highly detailed full color plans

- Materials list

- Step by step instructions

- Plywood cutlist and sheet goods cutting plan

- Illustrations & pictures showing each step

You will need Adobe Acrobat reader to view the file. Most computers already have this installed. For a free download click here.

21 reviews for Table Saw Crosscut & Miter Sled Plans

Related products

Sverrir Hjörleifsson –

Do you have the plan with meters measurments ?

Nick (verified owner) –

I don’t as of now but remember 25.4mm to an inch

umpire20 –

I recently purchased and read your plans for this sled “combo” and they are absolutely EXCELLENT. I’ve never seen such a detailed step by step set of plans. It was like “reading your video”. They are certainly worth the price to purchase them. Kudos to you, sir.

I’ve ordered the parts necessary for this build and am awaiting their arrival. I’ll try to post a picture when I am through making my sled. Thank you………

Nick (verified owner) –

Thank you – I can’t wait to see it!

Mark A. Brown –

Seriously considering your plans. However, one thing you might want to add that has me holding off is the rough cost of the parts/pieces you used. The wood is a given as anyone can price that at their local lumberyard. Not knowing the cost of other parts you purchased that are pretty integral to your design has me hesitating to pull the trigger on your plans.

Nick (verified owner) –

the reason I left the price of materials out is because of the varied ways in which to build it – some have even built it without any aluminum parts – I used Kreg products but they are a lot of other manufacturers and their prices vary widely

Mark Burrs –

Your videos rock. I look forward to building this sled. My only outstanding question I need to answer for myself is if I want to make it with an open front or with a fixed depth. The one I whipped together has a fixed depth and I keep coming across situations where the wood is too big.

Any thoughts?

Nick (verified owner) –

thank you! – The main reason for having a back is to keep the 2 halves stable and keep the blade kerf a consistent gap so it doesn’t pinch the blade – as for larger pieces I would most likely make a panel sled or use another way to cut it to size

RHINO (verified owner) –

I was disappointed that I did not win this. I really need one ! I guess I will have to download your plans and make it myself. I suspect your other subscribers will too. Do you think it can be made without a bandsaw and some of the other tools you used ? I have a jigsaw and 3 x 18 sander and drills and other hand tools I priced the Kreg items on Amazon. It can be built for $250-300, depending on local cost of material. Any suggestions are appreciated.

Thanx

JRR

Nick (verified owner) –

you can most definitely use a jigsaw in place of a the bandsaw – it might just take a little longer – another thing to keep the cost down is to use cheaper plywood (I used baltic birch) or leave out the Top Trak on the fence – you could just use a clamped stop block – personally I like the convenience of it, but you don’t have to have it – hope that helps!

Kevin Kemp (verified owner) –

I built this last weekend and I love it. I got the plans which are very well done. The video was extremely helpfu too. Top notch stuff. I looked at different sled projects and I think this one is significantly better than any others I found. I used different but equivalent parts that i got from Woodcraft. I did use the Kreg miter guides which I have to say I’m not real impressed with them The quality is not consistent. One of the guides worked fine, but the other one was horrible. The set screws were so tight I could barely get them adjusted without damaging the screws. I think next time I need a miter I’ll try a different brand.

Nick (verified owner) –

glad you liked the sled and were able to build it – as far as the miter tracks, I spoke with Kreg and they said they had a bad batch from manufacturing and pulled the bad ones from inventory and corrected the problem – some unfortunately got out – they will replace any defective ones free of charge – so check with them for a replacement

Jon –

Hi Nick, why do you suggest that when gluing your sled base to the runners, we offset the center of the

plywood 1 1/2″ to the left of the saw kerf? I am not sure I understand the operation or reason.

Nick (verified owner) –

so when you utilize the rip fence as a stop block you are not equidistant to the left and the right of the blade – for example the stop block to the left of the blade goes from say 0-10″ and the fence picks up at say 8.5″ to your fence system size – granted I just used generic number for that example – doing the offset allows for an overlap of measurements to get to – hope that helps

Jon –

Thank you for the reply Nick. Much appreciated.

If you happen to have a chance, would it be possible for you to sketch out what you mean visually about the center offset of the sled to the saw kerf?

It would be a huge help to us visual learners. Perhaps append it to the Episode 58 post?

Thanks again.

Nick (verified owner) –

no problem – I will see what I can do – crazy backed up on stuff now – heck, I’m still in Atlanta from the woodworking show

Michael Prochaska (verified owner) –

I purchased your plans I think they a great. I do have a question that I posted on you tube today. I appreciate it if you could help me her is my post. This is a great video thank you for all the great advise. Was wondering on the miter slot tracks on top of the sled you went 4 1/2 inches from the kerf. I cant cause I would be sawing threw the screws from the runners on the bottom. I can make mine 3 1/4 inches or 5 3/4 inches. Which would you recommend? Thank you

Nick (verified owner) –

either distance should be fine – I would probably make it the 5 3/4″ to keep the hold downs a bit further apart – that would keep the miter insert more stable against twisting – it shouldn’t twist either way though – I do have plans for add-ons in the future and again either the 5 3/4″ or 3 1/4″ should work with those – hope that helps

Daniel (verified owner) –

Hi Nick. Your table saw sled design rocks! Bought the plans and have already built the sled but at a slightly smaller scale. Im getting rid to build the miter sled insert this weekend hopefully for some picture frames I want to build. My only question is why did you add miter tracks to your miter sled? Was this purely for the use of stop blocks on smaller pieces of work or did you have something else in mind? Thanks again and keep up the great work!

Nick (verified owner) –

thanks – mainly for stop blocks but I may try and incorporate some other things using them – showed using the stop blocks here

Jared J Treser –

Purchased these plans a few months ago (right before the giveaway) and I can honestly say, these were the easiest plans to follow! I used melamine for the base and both front and back fences as I found my plywood to be too warped to make an accurate sled. Worked great though! Absolutely love it, recommend to anyone on the fence about purchasing it. Ya, could have made a basic sled without them, but this is top notch. Thanks

Nick (verified owner) –

Wow, thanks Jared – glad you liked them and glad to hear you enjoyed building it!

Paul (verified owner) –

I just purchased your plans, and starting to get all the materials needed for the build – can’t wait to start building! Quick question: I don’t have a dato blade set, but thinking about purchasing one for this project – Any recommendations? Looks like Freud SD208 could be a good option, what do you use?

Nick (verified owner) –

As of today, this is my dado blade set – the Freud set looks pretty good too but I have yet to use it – I’d like to test out the difference between the SD208 and the SD508 – having a truly flat bottom to the cut is my biggest concern – my current one does that really well

Russ (verified owner) –

I purchased your plans and have the sled mostly complete. I’m working on the miter portion now and I’m wondering about the utility of putting the T-tracks in the miter portion on top of the miter rails vs. on the front? This might allow for T-track hold-downs to be used for loooong pieces – those that are too long some sort of basic stop.

Thoughts?

Thanks!

Nick (verified owner) –

I used them for stop blocks when doing picture frames – I show it a bit here – https://nickferry.com///2015/08/how-to-make-a-shadow-box-ep59/

Bryan Babbitt –

Hi Nick,

I am a new subscriber and very very new to woodworking. In fact, I have a hard time reading a tape measure lol. However, I am on a mission to get better at this. I have been learning about the table saw sled and thus far, your build has been my favorite and I would like to build it but here is my concern. I have a small Dewalt compact job site table saw. Not know much about all the sleds and amazing jigs that are out there.. would this build work for my saw as well?

Thanks for feedback you can provide and keep up the great content! I am really enjoying your videos! Now if I could just make some of the things you make and do it as gracefully as you make it look!

Bryan

Nick (verified owner) –

thanks Bryan – you are not the first I will not be the last that has issues with tape measures – practice makes perfect – the sled would absolutely work – when making the base, size it up a bit and see how big you can go without it being a tipping issue – most likely taking 3-4″ inches away from the depth of the base should do the trick

Eric (verified owner) –

Great plans. Had a little issue with the download but Nick quickly responded to my email and took care of the situation, no problems. Looking forward to building this sled.

Miles (verified owner) –

Thoroughly enjoy watching your videos, and was pleased to be able to buy these plans and support your channel. Looking forward to making this sled… It’s by far the nicest one I’ve seen in looking the past couple weeks on YouTube. Thanks Nick!

Nick (verified owner) –

I appreciate you saying that – you will have to let me know how the build goes – I really love mine and use it all the time!

Chad (verified owner) –

Hi Nick, enjoyed watching this video and I am definitely buying your plans for this sled! I am just getting started in woodworking and I have little to no experience. I was given a few items from my dad and it just seems to be a great hobby to start up. A question I have is, what brand table saw are you using in your video to make this sled? The table saw I was handed down is a 10″ craftsman….it is so much louder and more clunky than most saws I see on youtube. Is this an ok saw to start with, or should I look to upgrade right away? I don’t know where this hobby will end up just yet, but I do plan to make some nice things and don’t want to be held back by sub-par equipment. Thanks for your time.

Nick (verified owner) –

I have most of my tools listed here – https://nickferry.com///my-tools-equipment/ – nothing wrong with the saw you have if it does the job – upgrade over time if you want something quieter and more accurate and the work you do calls for it

Mario (verified owner) –

I just received your plans and I’m looking forward to the build. I’m just getting into woodworking and purchased my first table saw, a Bosch TS3000. I have built a couple of beginning projects with good results; but, the more research I do, the more I want the sled combo. My concern is I might be starting off to big. The saw tabletop is 21-1/2 X 40-1/2 (fully expanded) with the blade 11-3/4 from the left side. Am I aiming to high for my first sled or will this design work for my size saw? Thank you for any assistance in advance.

Mario

Nick (verified owner) –

congrats on the new saw! Mine table top is probably 43″ wide by 24 or 25 deep so you’d probably want to make the sled 4-6″ less in depth to keep it from tipping – hard to say without actually being there though

Joseph (@mrjoedave) –

Love the channel! Just about to get a new saw delivered. This will be my first project. I thought I remembered seeing a tenon jig you made for it also. Is that right, or am I confused?

Also, has anyone done removable throat plates for this? It seems like that would be nice to have, but maybe I am over thinking it.

Nick (verified owner) –

thanks much – you can see the tenon jig build here, and the cut-list for it here – I had thought about a throat plate for dados but never pulled the trigger on it and have no regrets on not having it

Barett Engelhardt (verified owner) –

Can 3/4″ MDF be substituted in place of Plywood?

Nick (verified owner) –

you could but it would be substantially heavier and won’t have as much resistance to bending

Lee (verified owner) –

This may be s dumb question but doesn’t cutting through the aluminum mess up the blade on your table saw?

Nick (verified owner) –

not a dumb question at all – it’s not the most well known thing to do – cutting aluminum like this is perfectly fine to do with carbide tipped blades – A higher tooth count blade typically works better – yes it will dull the blade quicker than cutting wood but that’s how it’s done in manufacturing all the time